Introduction: From Sea to Shelf

Ever wondered how canned tuna is made? Behind every can of Doomsho tuna lies a journey of freshness, precision, and quality. From open waters to advanced canning facilities, the process ensures safety, nutrition, and rich flavor in every bite. In this article, we take you inside the tuna production process and show you what makes Doomsho tuna stand out in the global market.

Catching the Fish: It Starts in the Deep

The journey begins with sourcing high-quality tuna from the southern waters of Iran and nearby oceanic regions. Fishing vessels equipped with sustainable practices catch only the freshest, fully grown tuna. This ensures both ecological balance and top-tier meat quality for processing.

Key Points:

- Only mature, healthy fish are selected

- Caught using sustainable, ocean-friendly methods

- Immediate chilling on board to lock in freshness

This is the first step that sets Doomsho apart from mass-market brands.

Processing and Cleaning: Maintaining Purity and Safety

Once the fresh tuna arrives at the Doomsho processing facility, it undergoes immediate and hygienic handling. Cleanliness is not just a standard—it’s a ritual. Each fish is inspected, weighed, and prepared for cutting by trained professionals following strict safety protocols.

Main Steps Include:

- Careful washing with filtered, food-grade water

- Removing bones and skin with high-precision equipment

- Sorting the meat based on texture, color, and fat level

By the end of this stage, only the finest cuts move forward. This attention to detail ensures that every can of Doomsho tuna is consistent in quality, texture, and taste.

The secret to great tuna? Clean cuts, clean processes.

Cooking and Canning: Sealing in Freshness

After the tuna is cleaned and portioned, it’s time for gentle cooking—a crucial step in preserving both flavor and nutrients. Doomsho uses steam-cooking methods that minimize nutrient loss while enhancing the tuna’s natural texture and color.

What Happens Next?

- The tuna is lightly cooked to maintain moisture and flake integrity

- Pieces are packed into sterilized cans with high-quality oil or brine

- Each can is vacuum-sealed and hermetically closed to ensure long shelf life

The entire tuna production process is monitored in real-time by quality control teams. No can leaves the line without passing multiple checks for temperature, weight, and seal integrity.

With Doomsho, every can locks in the sea’s purest taste — nothing added, nothing lost.

Sterilization & Labeling: Safety Meets Style

Once sealed, every can of Doomsho tuna enters the sterilization chamber—a high-pressure steam system that eliminates all potential bacteria while preserving taste and texture. This step is key to ensuring long shelf life without using chemical preservatives.

Final Steps Before Distribution:

- Heat sterilization at controlled temperatures

- Automated labeling with traceability codes

- Lot tracking for export certification and compliance

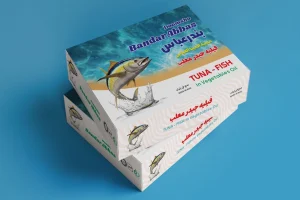

After sterilization, cans are cooled, dried, and labeled with custom Doomsho packaging—designed for impact and durability in global shipping. Whether sold locally or exported overseas, every package reflects the quality inside.

At Doomsho, our packaging isn’t just protection—it’s a promise.

Conclusion: From Tradition to Innovation — The Doomsho Difference

Now you know how canned tuna is made — a journey that begins in the deep ocean and ends with a can full of flavor and trust. At Doomsho, we combine local expertise with global standards to deliver a product that’s fresh, clean, and ready for any table worldwide.

Every step of the tuna production process—from catch to canning—is handled with precision, safety, and pride. That’s how Doomsho tuna earns its place on international shelves and dinner plates alike.

🔷 Ready to Import or Distribute Doomsho Tuna?

Join our network of global partners and bring Iran’s finest canned tuna to your market.

👉 [Contact Us Now]